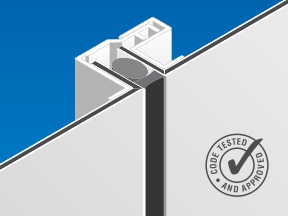

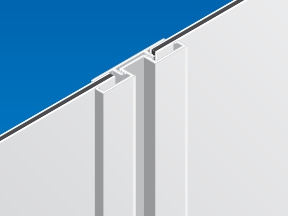

All the benefits of a tested ACM / MCM in a system that can be fabricated on-site, paired with a quick lead time makes these products the optimization of value. Offering the ultimate in high-end aesthetics and performance, these systems provide both wet and dry sealed options to meet the most demanding requirements.

Citadel Architectural Products

6198 W Airport Blvd

Greenfield, IN 46140

Copyright All Rights Reserved © 2024 | Website Design by Matt Gerber Designs

www.elementpanels.com

Logan Raivio

(503) 487-0822

logan@elementpanels.com

Mike Watson

(469) 518-5860

mike@elementpanels.com

www.elementpanels.com

Logan Raivio

(503) 487-0822

logan@elementpanels.com